How do you plan for dehumidification needs to an upgraded cannabis grow operation?

If you’re getting ready to upgrade your cannabis grow from the semis to the pros, there are a lot of considerations as you plan out your new operation. Aside from all the horticultural details, facility details are massively important.

Indoor, outdoor, or greenhouse? Lights, air movement, CO2? Integrated system controls?

Given the sensitivity of cannabis plants to disease stemming from sub-optimum growing conditions—and the likelihood of crop loss as a result of these problems—grow room humidity control should be at the top of your consideration list.

But how do you plan for dehumidification needs for an upgraded cannabis grow operation? Where to begin? We talked with a few experts in the field for some tips.

Do the Math for your Cannabis Grow Dehumidification Needs

Joaquin Morelli’s experience ranges broadly from wilderness survival instructor to carpentry, mushroom farming and cabinetmaking. Taken together, the wide range of experience prepared him for the challenge he’s undertaken for the past 2.5 years as the facilities director for Grow Op Farms in Spokane, Washington.

“At the time I started, we had only a quarter of our current operation,” he said. “I’ve had the opportunity to develop most of our now 60,000-square-foot facility from the ground up. The industry is young, so many of the processes have never been scaled out at this level. The trick is to stay flexible and learn quickly what works and what does not.”With all that experience in scaling a cannabis growing operation, what is Morelli’s number one piece of advice when it comes to grow room dehumidification?

“The essential idea is, it’s a contained environment. When you feed the plants, you’re introducing a measurable amount of water into that environment—the water has to go somewhere. If you do the math and figure out where it all goes, you will know what needs to be removed through dehumidification.”

Cannabis Grow Room Dehumidification Variables:

Morelli notes that there are three main variables in the equation that will help tell you how much water you will need to remove from your environment:

1. Runoff

Morelli said while different growers will approach runoff differently, the Grow Op team aims for 10 to 15 percent runoff to assure that their pots are flushed out.

2. Plant absorption

Morelli and the team at Grow Op assumes only about 10 percent of the water given to plants will be absorbed by the plant.

3. Evapotranspiration

Once you’ve taken your base amount of water fed per day, subtracted runoff and plant absorption, you can estimate how much moisture will be let out into the room via evapotranspiration. Of course, transpiration by itself is a complicated subject, but at this point you’ll at least have a ballpark number to work with.

4. AC system

Once you’ve got your ballpark figure on the amount of water that needs to be removed from your grow room, you will need to consider what will already be pulled out via your temperature control system.

“Growers will always have some sort of air handler or AC system, even if they’re just starting out,” Morelli said. “It does pull some moisture out of the room, but it doesn’t pull all of it and really they’re not designed to do that, especially the ones in the budget range you end up with when you’re first starting out.”

You need a bearing on how much water your AC is pulling out of the room, and Morelli suggested the best way to do that is isolate the condensate line coming out of the AC over a 24-hour period.

How Many Dehumidifiers do you Need for your Cannabis Grow?

Morelli said you might be able to estimate, for instance, that about 70 percent of the water given to plants each day will need to be removed from the environment to keep it from getting overly humid, which can breed crop-killing molds and mildews.

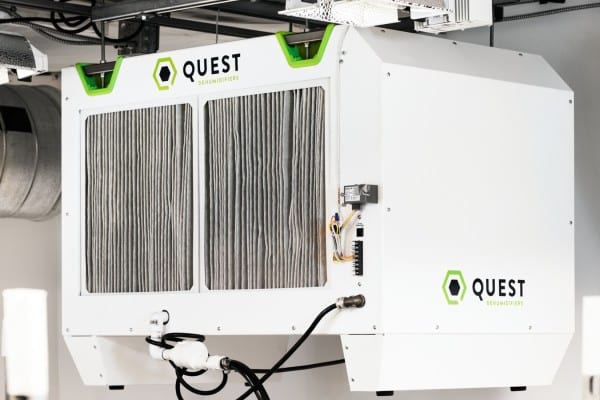

“Say your AC will pull out 450, 500 pints per day, that still could leave you with 600 pints per day to pull out,” Morelli said. “You can see right there, how much dehumidification you need. I do use quite a few Quest machines in a building, probably 25 of them, the one we use most is the 205—the 205 being the pints per day (PPD) of water it pulls from the air. So if you need to pull 600, it’s going to take at least three of these to handle that 600 pints that are left.”

The exact number of dehumidifiers recommended can vary, however. For especially large grows, the Quest 506 might be an even better option. The 506 is the first 500-pint commercial dehumidifier on the market, designed specifically for growers.

Morelli said he prefers to add about 30 percent to his estimate of the number of PPD he needs removed from the environment because relative humidity changes throughout the day.

“During the day when the lights are on, the plants are transpiring a large amount. At night they don’t transpire, so there’s not much moisture being produced, it’s just minor evaporation for the most part,” he said. “Anyone who’s using data loggers knows that when lights go out humidity spikes, so during that spike, having enough dehumidification in there to take the top of that spike off quickly is important.”

All-inclusive Systems or Standalone Dehumidifiers for your Cannabis Grow?

For a large, upgraded cannabis grow operation, an all-inclusive air-handling unit may seem like the smart choice. But Morelli cautions against being too quick to pull the trigger on such a system.

“I think the cost of solving for all of your environmental controls through a mechanical firm that brings in an all-inclusive system—one that takes care of your temp and your humidity, likely by bringing in a rooftop unit—that can be risky.”

“The mechanical contractor isn’t necessarily accustomed to taking care of the humidity in a major grow environment. So, I think you should always have standalone dehumidification units. It may mean having secondary controls for just your humidity equipment—though if you want to spend the money you can get it all integrated” he said. “The reality is you’re opening yourself up to vulnerabilities when you contract out your complete system to folks who are working in a new territory. Grow operations are just different.”

One of the problems with an all-in-one environmental control system is a lack of flexibility.

“Getting your own high-quality commercial dehus is an asset in the sense that you figure out what works. A lot of these HVAC systems require a tremendous amount of tuning as seasons change, and you don’t have flexibility if you have just one rooftop unit,” Morelli said.

Staging Dehumidifiers for your Cannabis Grow

Another key consideration for upgrading your cannabis grow is the speed at which your equipment ages.Let’s say your new, upgraded grow has many dehumidifiers, and your setup involves progressing through a sequence in which more and more dehumidifiers power on as humidity goes up. It’s important to rotate your staging over time so that the total run time on your equipment is balanced.

“Your machine, for the first stage, will be used more than the fourth machine in the sequence, and it’s important to track those machines over time,” Morelli said. “The ones in the front need to move to the back. You want to pace all your machines to age out at the same time—this is important in terms of long-term maintenance.”

“When you have 25–30 of these things floating around it adds up quick,” he added.

The fact is, there are a lot of considerations when you’re thinking about upgrading your grow. It certainly involves some complicated math, big decisions and likely some fine-tuning over time. But whatever you do, don’t overlook humidity and climate control—it’s too big of an investment to get wrong.