What Makes a Good Grow Light?

Whether you are a novice cannabis grower wanting to take your closet grow to the next level or an experienced grower looking to replace an old lighting setup, the science behind grow lights has come a long way over the last few years and making sense of all the choices out there is essential to growing happy and healthy plants. The biggest leaps in lighting technology have come with the development and advancement of light emitting diodes (LEDs). While growers who experimented with early generations of LEDs may have had a poor experience, LED technology is light years ahead of where it was just a few years ago and many of the challenges growers had with the early LEDs have been overcome. When considering your next grow light purchase, here are some of the key factors you should look at when comparing different lighting options.

1. Spectral Distribution

Spectral distribution is used to describe what wavelengths a light source emits on the electromagnetic spectrum.Spectral distribution is important to consider when determining what grow lights to buy because cannabis plants rely most heavily on only certain portions of the spectrum for photosynthesis (the process by which plants use light to create the food they need to grow) and different lights emit different wavelengths of light or spectral distributions.

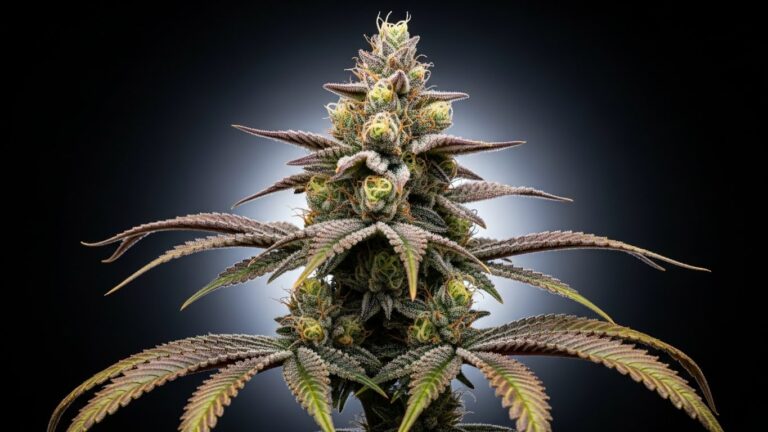

Cannabis plants are particularly receptive to the ends of the visible light spectrum depending on where they are in their growth cycle. In early growth stages cannabis plants crave blue light (400-500 nanometer wavelengths). When cannabis plants start flowering they need red light (600-750 nanometer wavelengths).

Traditional high intensity discharge (HID) lights tend to emit a wide spectral distribution providing more green, yellow and orange light than blue or red light. This means a lot of energy is wasted because it is being used to produce light that cannabis plants can only use a small portion of. The wasted energy is converted into heat, which means more energy (and money) must be used to keep the growing environment at the optimal temperature.

LEDs on the other hand are advantageous because they can be adjusted to provide the precise spectral distributions cannabis plants need at any point in their growth cycle. As a result less energy (and money) is wasted, and your plants will be healthier and happier.

2. Photosynthetic Photon Efficacy (PPE)

PPE is a measurement used to compare the efficiency of one light source to another. All you need to know about PPE is that grow lights with a higher PPE are more efficient than grow lights with a lower PPE. HID lights have a PPE of 1.7 to 2.0 at best, whereas best in class LEDs like the F1V by Fohse have a PPE of 2.4 to 2.7. Growers can expect to save anywhere from 35 to 50 percent on energy costs by using a 2.7 PPE light compared to a 1.7 PPE light. In the near future Fohse plans to produce the first cannabis grow light with a PPE of 3.0 or higher.

3. Maintenance Costs

Electrical costs are only a portion of the costs that must be considered when determining what lighting solution is best for you. Maintenance costs often go overlooked, but can easily add up. Between replacing light bulbs and ballasts, traditional HID lights have very high maintenance costs. Generally speaking HID bulbs cost anywhere from $100 to $150 a piece, and will need to be replaced every or every other harvest. In addition to bulbs, ballasts will need to be replaced roughly every three years at a cost of up to $600 dollars a piece.

LEDs on the other hand do not burn out and do not require separate ballasts. Rather than burning out, LEDs fade over time. Even though LEDs often cost more up front than HID lights, they provide a greater return on your investment over the long run. For example, Fohse’s best in class LEDs take 50,000 hours of use (equivalent to eight or nine years) before they fade to producing 90 percent of their original output (a measurement also known as L90) and take nearly 110,000 hours of use (almost 20 years) before they fade to 70 percent of their original light output (or L70).

4. Ingress Protection

Ingress protection, or IP, refers to how resistant a grow light is to some of the major environmental factors commonly found in grow operations; dust, mold spores, spider mites, and water. All of these environmental factors can wreak havoc on a grow operation if the right precautions aren’t taken, so having well protected lights is crucial.

Growers who use older HID setups that have low IP ratings must be extremely careful when watering their plants, and may even have to remove and meticulously clean their lighting equipment when a suspected containment has been introduced into their crop. They then must take the time to reinstall their lighting while still risking the potential of reintroducing the original containment to their growing environment.

A perfect IP rating is IP68, meaning the appliance is 100 percent dust and waterproof. Today it is not uncommon to find LEDs with a rating of IP44-IP57, and best in class LEDs can claim up to a rating of IP67. With IP ratings of this level growers can water their plants without worry, and rest easy knowing that their crop is not at risk of being contaminated by dust caught in their lights.

5. Color Rendering Index (CRI)

A light’s CRI is a measure of how true to a reference light source a given light source is. For example, if you are looking at a plant under the sun the colors of the plant are going to look very specific. If you take that same plant and look at it under an artificial light it likely won’t look the same. That means the artificial light has a low CRI because the light it is emitting is much different than the light the sun is emitting. However, if you took that same plant and put it under an artificial light and it looked almost the same as it did under the sun, that light has a very high CRI. Having lights with a high CRI is important because you may not be able to detect contaminated, sick, or malnourished plants as easily under low CRI lights.

Author Bio:James Bradley is the Chief Marketing Officer forFohse, Inc.,a company dedicated to engineering efficient solutions for the cannabis industry. The company has developed the very first LED cannabis grow light capable of outperforming traditional HID systems at significant cost reduction.