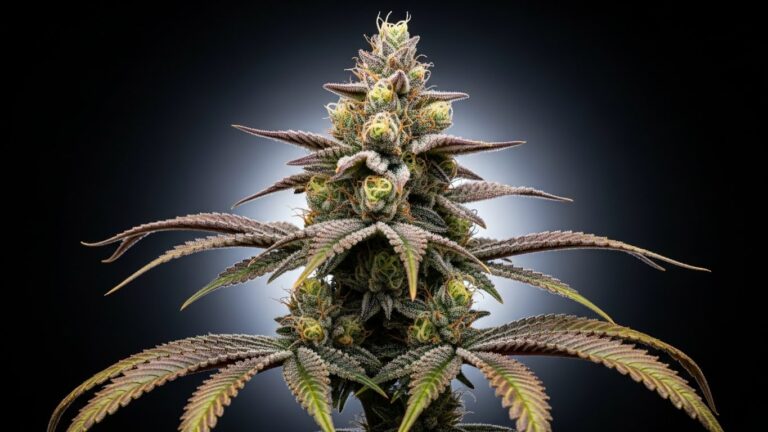

As cannabis cultivation transitions into large scale commercial facilities, growing practices are evolving. Today’s facilities are becoming truly state-of-the-art. As the demand for cannabis increases, so does the supply, and therefore the need to produce your crop efficiently. There are also many variables within each locality to remaining complaint and sustainable. This is where technology solutions are playing a huge role.

Big agriculture already has many best practices that are now being adopted by the cannabis industry. Ag-tech can refer to both mechanical as well as digital technologies. Here we will look at fertigation, lighting, environmental automation, benching, and big data.

Irrigation / Fertigation

Gone are the days of hand watering. Following in lock-step with big agriculture, expect to see well-designed, built, and maintained fertigation. When all the plants receive a consistent amount of water and nutrients to the plant zone they will grow uniformly. These pressurized and automated lines make sure no one plant is receiving too much or too little water or nutrient mixes. The systems can generate notifications if there is an error on the line. These systems can also be built to include water treatment such as reverse osmosis. Professionally designed systems also take into account waste water and how it needs to be treated before being returned into the local municipality’s water system. These systems can be hooked into the software brains of environmental automation.

Lighting

Lighting is a big part of indoor cannabis cultivation. Whether it is in a warehouse or a greenhouse with blackout shades to control the light. HPS and CMH are long-time industry standards, however, even the lights and the associated design plans to maximize light levels with less fixtures are improving. Additionally LED is taking hold in the industry, with many more facilities moving to checker-board their facility with HPS and LED. The lights also tie to control boards that automate the on and off times for the light. Some lights, such as the Soleil® lighting line, also come with dimming capabilities to replicate sunrise and sunset. The right reflectors, especially the ones that need minimal maintenance help to maximize light output. Re-lamping lights also guarantees light levels to ensure sustained yields.

Environmental Automation

Every aspect of an indoor grow can be controlled to a high degree regardless of variable weather outside. Each factor from temperature and relative humidity to lighting and fertigation, can be tied to an automated system. Instructions are inputted and can be executed with fine precision. The software collects the data in real time from lights on or off, to temperature adjustments and air flow, to the movement of employees throughout the facility. There are a series of conditional commands that can prompt the system if any number of variables are met. The software can be accessed on a desktop as well as a mobile and notifications and alarms can be programmed to be sent to key people in the facility when something needs their attention. Examples of this technology include Argus and Soleil® Controls.

Benching

Although this is strictly mechanical, the right rolling or vertical benching installation can be one of the most effective at significantly increasing yield. By making the most of the available square footage in a grow, benches can be rolled making better use of what was previously fixed aisle space. Or with stacked benches in veg, the space is effectively nearly doubled. This technology is commonplace in large agricultural facilities. In addition to space optimization, benching provides a clean, dry surface to get plants off the ground. It also proves to be more ergonomic for workers and minimizes plant exposure to disease. For rolling benches there is the option of Drain to Waste or Staal-Plast Ebb & Flow Trays irrigation parts. Staal-Plast has 30+ years in large scale horticulture and floriculture and is the only company in the world making high-impact polystyrene molds. Other top options are Expanded Metal and 2″ x 2″ Wire. These are appropriate for any stage in production, but will not catch water. Whatever your choice, this investment will directly impact yield output, IPM (integrated pest management), and worker ability to access plants easily for better maintenance and care.

Big Data

One of the fastest developing areas of ag-tech adoption is in the area of big data. It is the key to maintaining consistency, which is required to produce a quality cannabis crop with the maximum yield possible. Data collection and analysis is definitely the future agricultural technology which aims to eliminate human error and create unprecedented consistency in cultivation facilities. It can manage diverse ideal growing conditions for various strains and aid with the detailed record-keeping required for compliance. urban-gro in partnership with Edyza, has created a proprietary Time Synchronized Multiple Access (TSMA) channel method, to allow connectivity between thousands of things in close proximity with power efficiency unachievable by other methods such as BLE, Zigbee, UWB, or Wi-Fi.

Utilizing sensors in the soil, around the room, and even on the plants themselves, it allows constant, real-time analysis of the environmental conditions in a cannabis grow operation. Even employees can carry a tag to monitor which rooms they access throughout their shift. These sensors give immediate insight into the grow room, so key employees can remotely monitor key metrics. Coupled with Soleil® Control, this system can be integrated to control various aspects of the climate within the grow operation. Programmed to control lighting, temperature, humidity and air quality, Soleil® allows cultivators to define an ideal environment at every stage of growth.

Technological Edge

In an increasingly competitive and regulated environment, ag-tech solutions are what will help distinguish the leaders in large-scale cannabis cultivation. Companies like urban-gro continue to lead the way in helping cultivators identify, design, build, install and commission these technological tools. There is no doubt the right technology will help any grow be more efficient, consistent and informed about their facility and processes.